Views: 0 Author: Site Editor Publish Time: 2025-11-28 Origin: Site

Classification of Circular Knitting Machines: Different Fabrics, Different Machines

A circular knitting machine—also known as a circular weft-knitting machine (or more concisely, a circular knitting machine)—features numerous knitting systems (commonly referred to as "feeds"). For example, in a single-jersey latch-needle circular knitting machine, each knitting system consists of latch needles, sinkers, cam carriers, yarn guides, and other components. Each feed constitutes an independent unit capable of forming loops. Due to its high number of feeds and high rotational speed, this machine achieves high production output. Combined with excellent fabric quality, it offers strong product versatility, rapid pattern changes, and fewer processing steps—factors that have driven its rapid development.

During operation, the cylinder (or dial) of the machine rotates at high speed along its circumference. Under the control of cams, the needles perform horizontal weft-knitting motions (as opposed to vertical warp knitting). Essentially, loops are formed and stacked row by row in a horizontal direction, typically resulting in tubular fabric.

Since the fabric is knitted in a tubular form, does it need to be slit for use? Indeed, it is sometimes slit open. Once slit lengthwise along the wale direction using a slitting machine, the tubular fabric becomes open-width fabric, which is better suited for dyeing and finishing (as many dyeing and printing machines only accept open-width material), as well as for inspection and garment cutting. However, in certain applications—such as socks, cuffs, rib collars, seamless underwear, and seamless sportswear—the fabric must remain in its original tubular form and is therefore not slit.

Circular knitting machines are categorized into single-jersey and double-knit types. A Single Jersey Circular Knitting Machine, also known as a plain knitting machine or simply a single-jersey machine, typically features only one needle bed (the lower cylinder) and uses a single type of needle (latch needles or compound needles).

The term “Single Jersey Circular Knitting Machine” is the most standard designation; “Plain Single Jersey Knitting Machine” emphasizes the basic plain-knit structure. In daily usage, it is commonly shortened to “Single Jersey Machine”, which is fully understood across the industry. “Single” highlights its single-bed construction (in contrast to double-bed structures such as interlock or rib). “Jersey” originates from the traditional knitting techniques of Jersey Island in the English Channel and has become the standard name for plain weft-knit fabric. “Circular” indicates continuous rotary knitting on a circular needle cylinder—distinguishing it from flat knitting machines, which operate via reciprocating motion (Flat Knitting). Circular knitting is thus referred to as Circular Knitting.

Circular Knitting Machines and Flat Knitting Machines represent the two core equipment categories in the knitting industry. They differ fundamentally in structure, operating principle, fabric form, and application: circular machines primarily produce greige (raw) tubular fabric, whereas flat machines can knit shaped garment components—such as collars—or even entire seamless sweaters without additional sewing. In other words, circular machines produce “fabric,” while flat machines construct “garments.”

A Double-Knit Circular Knitting Machine features two needle beds—the upper dial and the lower cylinder—and employs two sets of needles (upper and lower). A Rib Machine is a type of double-knit circular knitting machine. By industry definition, “rib” fabric must simultaneously contain both face-loop wales and reverse-loop wales; therefore, “single-sided rib” does not exist in theory. Other double-knit machines include Interlock Machines.

The two main categories of circular knitting machines are as follows:

(Single-Jersey):

Plain Single Jersey Machine

Single Terry / French Terry Machine

Three-thread weft-insertion machine

Single Jersey Jacquard Machine (divided into mechanical and electronic needle selection types):

Mechanical Single Jersey Jacquard Machine, Electronic Single Jersey Jacquard Machine. Small-diameter single-jersey jacquard circular knitting machines are mostly mechanical, whereas large-diameter ones are predominantly electronic.

Weft-insertion Machine (also known as Weft Inlay Machine). Unlike a Three-thread weft-insertion machine—which employs three yarns per feed (typically a face yarn, a ground yarn, and an inserted weft yarn)—laid-in warp structures fall under the domain of warp knitting, whereas weft-insertion structures belong to weft knitting. Circular knitting machines are inherently weft-knitting systems: their high-speed rotating cylinder feeds yarns radially or tangentially from packages, making weft-wise loop formation natural and efficient. In contrast, integrating a true warp-wise yarn feeding system (e.g., vertically unwound warp beams) into a circular machine would cause severe issues such as yarn entanglement, tension instability, and frequent yarn breakage due to the rotational motion. Consequently, genuine warp-laid structures require dedicated warp knitting machines, not circular knitters.

(Double-Knit):

Plain Double-Knit Machine

Rib Machine

Interlock Machine

In southern China, the interlock knitting machine is locally referred to as“Dui Tong Ji” (“aligned-cylinder machine”). From a macro-mechanical perspective, the needle slots on the dial (upper needle bed) and the cylinder (lower needle bed) are arranged in a 1:1 perfectly aligned configuration—that is, their slots are physically collinear along vertical axes. However, because the needle tips face each other directly, if both upper and lower needles were to extend simultaneously, they would inevitably collide and cause severe damage. To prevent this, interlock machines employ a dual-needle-track control system combined with long-and-short needle arrangements (also known as “high-low heel needles”), ensuring that upper and lower needles operate alternately without interference.

The needle slots of an interlock knitting machine are arranged in a 1:1 configuration but with a strict half-pitch offset—meaning each needle slot on the dial is precisely aligned with the center position between two adjacent needle slots on the cylinder. This offset arrangement is fundamental to enabling the alternate loop formation by the dial and cylinder needles and preventing needle collision.

In southern Chinese factories, the term“Dui Tong Ji” originates from the machine’s most critical setup procedure: “Diao Dui Tong” (aligning the dial and cylinder).

Alignment requirement: During machine commissioning or maintenance, technicians must precisely align the needle slots of the dial with those of the cylinder so that they lie on the same vertical lines. Any misalignment will cause scraping or collision during the alternating motion of long and short needles.

Distinction from rib machines: Rib knitting machines do not require this “slot-to-slot” alignment—they use a “slot-to-tooth” configuration instead. Consequently, the term“Dui Tong” has become an exclusive identifier for interlock machines among double-knit circular knitting machines in the region.

The term “Dui Tong” is derived from the machine’s physical configuration, whereas “cotton-wool machine” originates from early production of thick, warm fabrics using cotton yarns that felted like a blend of “cotton + wool.” Although modern versions often use pure cotton or polyester-cotton blends, the name remains in common use. Therefore, the name "cotton-wool machine" is derived from a spiritual or conceptual dimension, and both naming conventions embody both "form" and "spirit".

Double-Knit Jacquard Machine (D-Jacquard), similarly divided into:

Mechanical Double-Knit Jacquard Machine, Electronic Double-Knit Jacquard Machine. The vast majority of modern double-knit jacquard circular knitting machines are electronic (Electronic Double-Knit Jacquard Circular Knitting Machines), as they require precise synchronized control of the needle selection mechanisms on both the upper and lower needle beds—a level of complexity that mechanical systems struggle to achieve.

Transfer Stitch Machine (available in both double-knit and single-jersey configurations)

Double Terry Machine

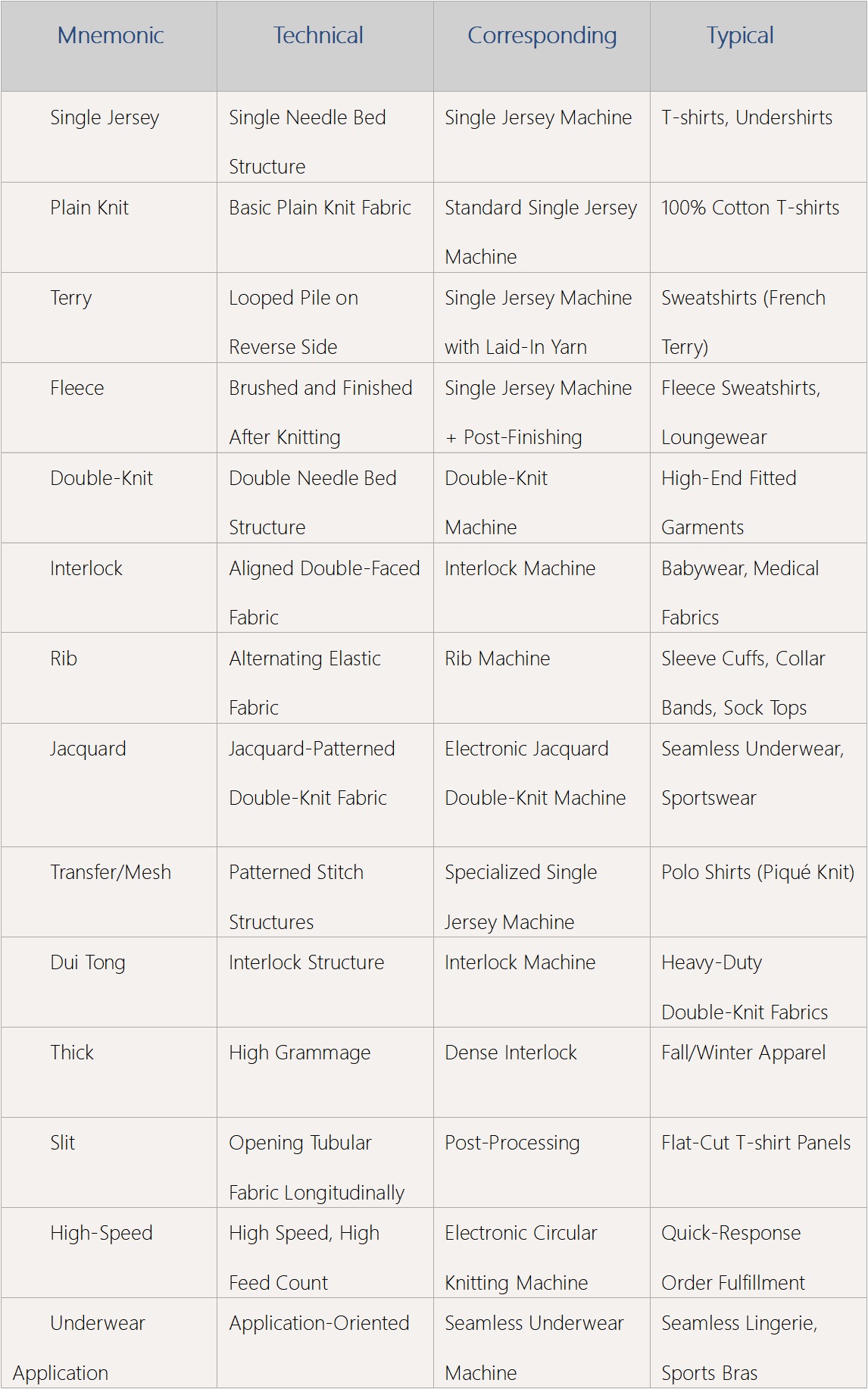

Quick-Reference Mnemonic: “Single: jersey, terry, fleece; Double: interlock, rib, jacquard; Transfer, mesh, aligned-thick; Slit, high-speed—underwear focus.”

First line: “Single: jersey, terry, fleece”

Single: Refers to single-jersey circular knitting machines.

Jersey: Basic plain single-jersey fabric (e.g., T-shirt material).

Terry: French terry fabric, featuring uncut loops on the reverse side. French terry is a single-sided terry fabric. However, not all terry fabrics are used for sweatshirts—for example, towels and bathrobes are made from double-sided terry fabric, which is not classified as french terry.

Fleece: "Fleece" denotes a circular-knit fabric whose reverse side has been mechanically brushed to form a soft, fibrous pile—commonly known as brushed back or fleece fabric. Therefore, strictly speaking, "fleece" is not a type of fabric structure but a finishing process.

Second line: “Double: interlock, rib, jacquard”

Double: Refers to double-knit circular knitting machines.

Interlock: Interlock fabric (cotton-wool fabric), produced on interlock machines.

Rib: Rib fabric, produced on rib machines.

Jacquard: Patterned double-knit fabric (jacquard interlock or rib), requiring a needle selection system.

Third line: “Transfer, mesh, aligned-thick”

Transfer: Transfer stitch or tuck stitch structures.

Mesh: Mesh or eyelet fabric (e.g., openwork knits).

Aligned: "Dui Tong" refers to interlock knitting machines—a colloquial term derived from the perceived "alignment" of the upper dial and lower cylinder. The fabric known as interlock is produced on these machines, commonly called"Dui Tong Ji" in southern China. Technically, an interlock machine is a double-bed circular knitting machine in which the needle slots of the dial and cylinder are precisely aligned in vertical registration—a configuration essential for its alternating knitting sequence. While "Dui Tong Ji" (literally “aligned-cylinder machine”) is widely used informally in Chinese-speaking manufacturing regions to denote interlock machines, it is not a standardized technical term in global textile engineering nomenclature.

Thick: Refers to fabric with a high grammage (weight per unit area) and a densely constructed structure.

Fourth line: “Slit, high-speed—underwear focus”

Slit: Open-width fabric, obtained by longitudinally slitting tubular fabric on a slitting machine.

High-speed: High-revolution, high-feed machines (e.g., electronic circular knitting machines with 96+ feeds).

Underwear focus: Key applications in intimate apparel and seamless garments.

See mnemonic chart below:

Terry is essentially towel fabric—think of the soft, fluffy layer inside bath towels or sports hoodies. These are actually loops of yarn that haven't been cut, which makes them highly absorbent and warm. Terry is commonly used for towels, hoodies, and loungewear due to its excellent water absorption and warmth.

Transfer is a knitting technique that creates openwork, mesh, or three-dimensional patterns. For example, the textured grid on the collar of Polo shirts or breathable sport T-shirts is often achieved by "transferring" loops from one needle to another. This method is ideal for creating ventilated and stylish sportswear.

Interlock is a thick, smooth fabric with both sides looking almost identical. It feels soft and has good elasticity, making it perfect for baby rompers, thermal underwear, and high-quality T-shirts. The fabric hugs the body without being scratchy, providing comfort and warmth.

Rib refers to the stretchy, elastic striped fabric used in cuffs, collars, and hems. It consists of alternating rows of face loops and reverse loops, allowing it to stretch and then return to its original shape. Ribbing is commonly used for shirt hems, sock openings, and hat edges to prevent sagging and maintain fit.

Single Jersey is the most common T-shirt fabric, featuring a smooth front side and a back side with fine wavy lines. It is lightweight and breathable, making it ideal for regular T-shirts, vests, and undershirts. It's affordable and comfortable, perfect for everyday wear.

Double-Knit refers to fabrics where both sides have loops, resulting in a thicker, more structured material that resists curling at the edges. It is suitable for sport jackets, children's clothing, and stylish knitwear that needs to hold its shape well.

Laid-in (or Weft Insertion) involves incorporating an additional yarn into the fabric that does not participate in the actual knitting process. For instance, adding spandex for elasticity or acrylic for warmth. This technique is frequently used in fleece-lined hoodies, stretchy leggings, and functional undergarments, enhancing their practicality.

Seamless doesn't mean no threads; rather, it refers to garments knitted in one piece using specialized circular knitting machines, eliminating the need for side seams. This results in a seamless finish that prevents chafing, making it ideal for sports bras, yoga pants, and seamless underwear.

Jacquard involves creating intricate designs directly within the knit structure, such as small logos, geometric patterns, or letters. Unlike printed designs, these patterns are formed by the loops themselves. Jacquard is used in high-end T-shirts, branded hoodies, and fashionable knitwear, offering durability and wash resistance.

Mesh is a breathable fabric with small holes, much like the ventilated areas under the arms or on the back of sports clothing. It is light, cool, and quick-drying, making it perfect for running shirts, basketball jerseys, and sun-protective clothing.

The field of circular knitting machines involves many technical terms, but in reality, new knowledge is simply an iteration of what you already understand—once you’ve built a solid foundation. You can’t become an expert overnight; instead, think of it as a strong core gradually incorporating new branches. Over time, with enough exposure and reflection, everything becomes comprehensible. And once that robust foundation is in place, innovation, progress, and the achievement of your goals all become far more attainable.

For example, single-jersey machines are used for T-shirt fabric, rib machines for collar fabric, and jacquard machines for sportswear fabric. While it is theoretically true that “multiple machines can produce the same fabric, and one machine can produce multiple fabrics,” in practice, there always exists an economically optimal or functionally best-suited machine for each fabric type. Production is allocated accordingly—each machine simply executes its designated knitting program as designed.